is brinell hardness test destructive|brinell hardness test chart : purchaser A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile . WEBPostamos vazados e vídeos "raros" que a maioria das pessoas tem curiosidade em ver. 🗂O que você encontrará aqui; 🆗Vazados 🆗Amador 🆗Packs 🆗Cornos 🆗Flagras 🆗Brigas 🆗Funkeiras 🆗Etc. Open a Channel via Telegram app. Preview channel. Don't have Telegram yet? Open via web telegram. or. Selecionamos os melhores vídeos .

{plog:ftitle_list}

WEBPuzzle sizes from 6 to 247 pieces. Embed jigsaw puzzles into your own web pages and blogs. Free online jigsaw puzzles with thousands of beautiful pictures and puzzle cuts. Control the level of difficulty for fun by all the family, or a quick distraction at work, or boring days. Send puzzle postcards to friends, puzzle of the day.

A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile .What is a Brinell Hardness Test? Standards of Brinell Hardness Testing. Brinell Hardness Test Procedure. 1. Preparation of the Specimen. 2. Selection of Load and Indenter. 3. Test Machine .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .If you need a quick, non-destructive measurement for a variety of materials in a manufacturing setting – the Rockwell hardness test is suitable. For softer materials or materials with coarse microstructures – the Brinell hardness test .

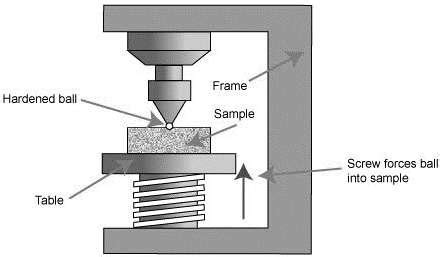

Brinell Testing Approach. The Brinell test is akin to giving your material a little love tap, but with a twist—it’s actually a strong punch to find out how tough it is. Using a hard metal ball as an indenter, we apply a heavy load to the material .

Brinell testing is a hardness testing method that involves applying a known load to a material’s surface via a hardened steel or carbide ball for a specific period. The size of the indentation left on the material gives an .

Brinell method determines the indentation hardness of metal materials, so this is not used on fully hardened or thin material. The Brinell test is used on materials with coarse grain or rough materials where the surface is .The Brinell test is frequently used to determine the hardness metal forgings and castings that have large grain structures. The Brinell test provides a measurement over a fairly large area .

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone without special training or skills. . and also the lesser cost is required to perform the test than other .Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic. Difference between, Brinell,Rockwell and Vickers Hardness Test What is .

Explanation: Brinell hardness test uses ball indenter. Its diameter is kept 1 mm for lower load 1 kgf. It is taken 10 mm for 500 kgf load. 7. Brinell hardness number is not a function of _____ . Non-Destructive Testing. Liquid Penetrant Inspection Eddy Current Inspection Radiographic Inspection. Best Reference Books. The Brinell hardness test is not always a destructive test; it depends on the context. While it does leave an indentation, it may not always be considered detrimental to the material's functionality. Explanation: The statement "The Brinell hardness test is always a destructive test" is false.Welding Hardness test is a type of non destructive test to ensure the integrity of the weld joints. That is performed as per ISO (International Organization for Standardization) standards ISO 9015 and 15614 Specification. But these both standards are not the same, both are used for different purposes. ISO 9015 has two parts, where Part 1 covers hardness testing of arc-welded joints. .It involves using a 5mm or 10mm round carbide ball to create an indentation in the material, applying a high test load (usually 750kg and 3000kg). The indentation is then measured and analysed using a microscope to determine the average result on the Brinell Hardness Number scale. Brinell Hardness Testing standards and specifications we work with:

Study with Quizlet and memorize flashcards containing terms like the indentation hardness test that applies a major and minor load to determine the hardness of a metal is called the, the destructive test that uses a weighted pendulum which strikes a notched test specimen is called the, "Endurance limit" is a term used in and more. Brinell hardness testing involves indenting a material's surface with a hard steel or tungsten carbide ball under a heavy load and measuring the diameter of the indentation. The Brinell hardness number depends on the applied load and resultant indentation size. . Rockwell hardness test is a non- destructive test used for soft as well as hard .

The Brinell test is similar in that an indentation is made, and the dent size is measured and then hardness calculated. But, Brinell is not a microhardness test, it is a macro test like the Rockwell. When evaluating plastic materials, a common test is the Shore Hardness. There are several scales of Shore hardness, a common one being Shore-D .

Study with Quizlet and memorize flashcards containing terms like Destructive testing involves subjecting weld samples to loads until they fail., Before a specimen is placed in a tensile testing machine, an accurate measurement of gauge length should be taken., In tensile testing, a weld piece is pulled until it breaks. and more.

The Brinell hardness test is always a destructive test. Select one: a. false b. true. Onset method. Which of the following methods is not an accepted method for determining yield point? Select one: a. Total strain method using extensometer b. Drop of the beam method c. Onset method d. Offset methodThe speed of the method is not very efficient relative to Brinell or Rockwell hardness test. Apart from the time which is consumed for the preparation of the test, it takes almost a minute to complete its cycle. . Still, If you want any further information about the Vickers test or any other non destructive hardness test methods then visit .

crystal hardness tester

Aerospace Materials and Processes Questions and Answers – Aircraft Materials – Hardness testing – Brinell and Rockwell Hardness ; Testing of Materials Questions and Answers – Indentation Hardness ; . Non-Destructive Testing. Liquid Penetrant Inspection Eddy Current Inspection Radiographic Inspection. Best Reference Books.Quiz yourself with questions and answers for Hardness testing, so you can be ready for test day. . non destructive test. vickers, brinell, rockwell, knoop. shore hardness scale. hv, vpn , vhn. 3 of 39. Definition. diamond pyramid. hardness definition. brinell shape. vickers shape. . brinell hardness test overview (brief)

To address this issue, non-destructive methods of hardness testing have been developed, such as ultrasonic and electromagnetic techniques. These methods allow for the evaluation of a material’s hardness without causing any physical damage to the surface. While traditional hardness testing methods can be considered destructive to some extent .Destructive testing (tensile test, hardness test, fatigue test, creep test and impact test) 2. Non-destructive testing (dye penetrant test, magnetic test, ultrasonic test, . This test is preferable to the Brinell test where hard materials are concerned, as it uses a diamond indenter. (Diamond is the hardest material known-approximately 6000 H Brinell Hardness Test | Procedure | Destructive Testing ( DT) | Methods | Basics | Telugu LectureHi This is Upendra Kumar Malla. Welcome to my channel .I wan.Study with Quizlet and memorize flashcards containing terms like Which one is not one of the advantages of hardness test over other mechanical tests? -Hardness being the most important property of the material in design problems -Correlation of hardness value to other properties -Non-destructive -Being cheap to perform, Hardness testing -cannot be used to definitely .

The Brinell Test. The Brinell test was invented in Sweden in 1900 by Dr. J. A. Brinell. This is the oldest form of hardness testing used today. It is frequently used to determine the hardness of forgings and castings that have a grain structure to course for Rockwell testing. Brinell is frequently done on large parts.Brinell Hardness Testing Services. The Brinell Hardness Test involves the application of a pre-determined test load to a fixed diameter carbide ball and the measurement of the subsequent impression with a Brinell microscope. Most commonly, it is used to test materials that have coarse structures or rough surfaces.The Brinell hardness test blocks are used for the yearly, indirect verification and calibration of Brinell hardness tester as well as the cyclic (daily) check of the hardness tester. . Non-destructive and destructive solutions. Coating thickness measurement Wall thickness measurement Measuring ferrite content Material analysis .

Study with Quizlet and memorise flashcards containing terms like Destructive Testing, Guided Bend Tests, Nick Break Test and others. . Hardness Testing. Measures a materials resistance to indentation. . (1/16') steel ball at a 10 kg minor load or 100 kg major load. Brinell Testing. Measures the diameter of indentation using a 10mm hardened .

brinell hardness tester diagram

Destructive Testing Results Learn with flashcards, games, and more — for free. . The Rockwell hardness test is the most commonly used and versatile hardness test. True. . A metal bar that breaks after repeated bending is an example of fatigue failure. True. The Brinell test is particularly suitable for very thin, case-hardened, or hard . #practical , #video , #dbatu , #sppu , #engineering , #materials , #metallurgy , #destructive , #testing , on EXPERIMENT / practical NO. : 02TITLE: - Destru. The indentation of the Brinell hardness is larger, and the measurement value is accurate, but it is not suitable for finished products and thin sheets. It is generally not classified as non-destructive testing. 6. The hardness value of Rockwell hardness is a dimensionless number, with no unit.

crystal mark hard drive test

Brinell hardness test: In this method, a hardened steel ball or carbide ball is pressed into the surface of the material under a specific load.The diameter of the resulting indentation is measured and used to calculate the material’s hardness. Vickers hardness test: This method uses a diamond indenter to make a square-shaped indentation in the material .

The Rockwell hardness test is a non-destructive testing method that is used to measure the hardness of materials. . The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional .

crystal reports hard drive test

crystal test the condition of hard drive

cscs card test is it hard

Resultado da Earthsounds (TV Series) subtitles - Earthsounds.S01E03.1080p.WEB-DL.DD+5.1.Atmos.H.264.LivelyEagleOfExoticSerendipity - Dutch Add OpenSub search Step 1 Click the "Accept and +Add" button to download OpenSub search Chrome Extension.

is brinell hardness test destructive|brinell hardness test chart